Specification

| Product Name | PLPG-350 |

| Speed | 5–30 m/min (adjustable) |

| Conveyor Belt Speed | 0–5 m/min (adjustable) |

| Min. Paper Width | 90 mm |

| Max. Paper Width | 320 mm |

| Min. Pleat Height | 16 mm |

| Max. Pleat Height | 72 mm |

| Operating Temperature | Up to 300 °C |

| Heating Power | 8.5 kW |

| Transmission Power Of Pleater | 0.75 kW |

| Conveyor Belt Transmission Power | 0.25 kW |

| Working Air Pressure | 0.6 MPa |

| Power Supply | 380 V / 50 Hz |

| M/C Weight | 1100 kg |

| M/C Size (L × W × H) | 7500 × 950 × 1750 mm |

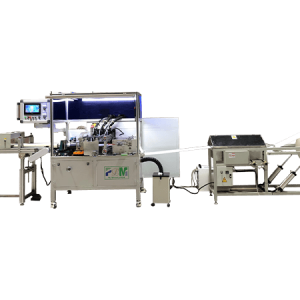

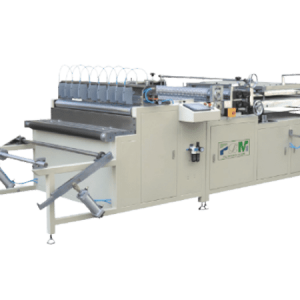

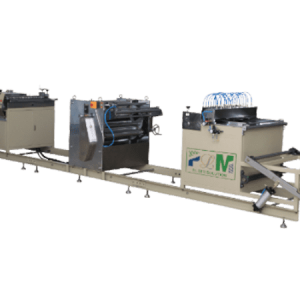

Components

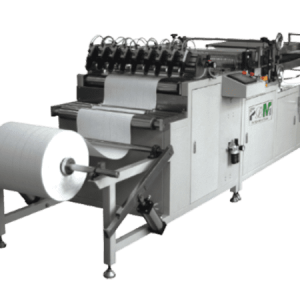

- Paper De-Coiler

- Water Steam Device

- Pleating Machine

- Hot-Melt Unit

- Belt Conveyor

- Automatic Counting

Features

- Both the work speed of the machine and transmission speed of conveyor belt are controlled by computer, and can be easily adjusted.

- Both impression and bubble formation are finished on the identical pairs of rollers with high precision.

- The temperature can be predetermined in accordance with the requirement of the technological process. When the pleating machine runs and the heater will start to work automatically.

- It adopts the water steam device, which is advantageous to prevent the paper from breaking when it is marked by rollers.

- Melt quickly, the glue dispensing quantity can be easily controlled by frequency converter.

- Set pressure control unit in glue feeding circuit to ensure the circuit safety.

- Both the rubber hose and nozzle are independently temperature controlled, and easy to operate.

Applications

This paper pleating production line is used for making the square air filter and ECO filter element.

Video

Downloads

To protect the documents privacy, please contact us to get the download password: info@pmfiltersolution.com

Reviews

There are no reviews yet.