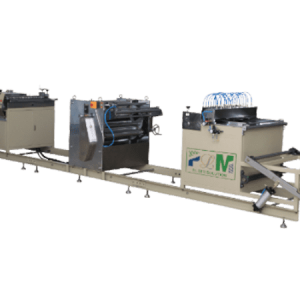

Specification

| Product Name | PLPQ-120 |

| Production Capability | 80–180 pcs/h |

| Adjustable Coil Diameter | 50–130 mm |

| Adjustable Coil Width | 70–120 mm |

| The Capacity of Holt Melt Unit | 10 kg |

| Heating Power of Hot Melt Unit | 6 kW |

| Power Supply | 220 V / 50 Hz |

| Working Air Pressure | 0.6 MPa |

| M/C Weight | 700 kg |

| M/C Size (L × W × H) | 2463 × 1219 × 2033 mm |

Features

- The rolling speed can be adjusted freely to appropriate tightness according to the size of the coil diameter.

- The three-stage counter and approach switch are used to obtain diversified coil diameter.

- Fast glue melting speed, glue feeding volume can be adjusted by the frequency converter easily. Rubber and nozzle are independently temperature-controlled.

- The injection cylinder controls the glue injected in the middle of, the left or right of the paper tube through the PLC program to ensure the paper core is free from glue leakage.

- The machine can heat the hot melt at preset time intervals automatically, which greatly saves the working time.

- This machine can pleat double layers of fuel filter paper.

- All electric elements are high quality imported elements with a long lifespan.

Applications

It is technically suitable for shaping the CAV coil paper of filter element.

Video

Downloads

To protect the documents privacy, please contact us to get the download password: info@pmfiltersolution.com

Reviews

There are no reviews yet.