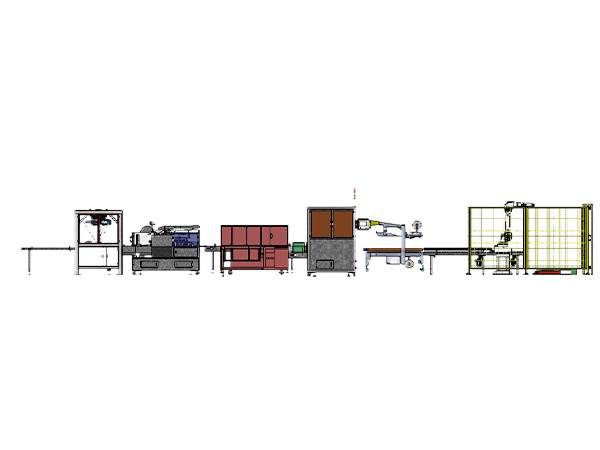

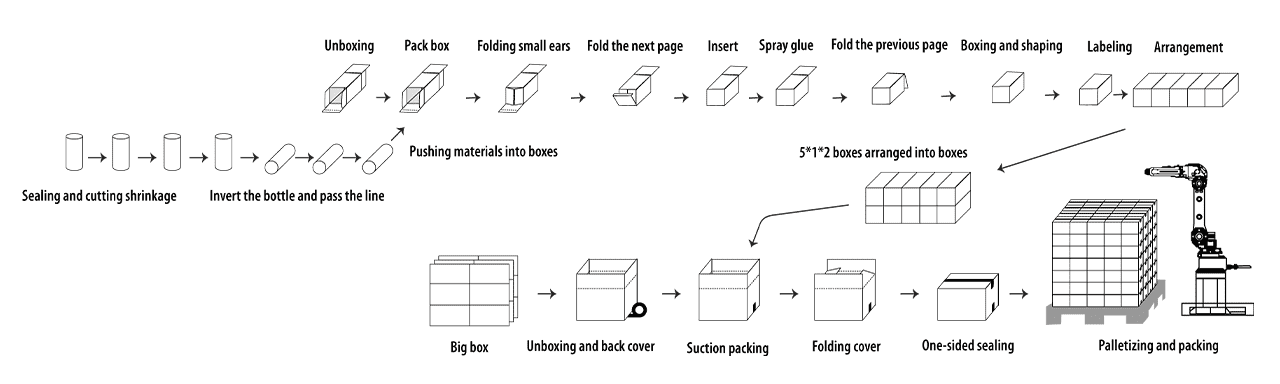

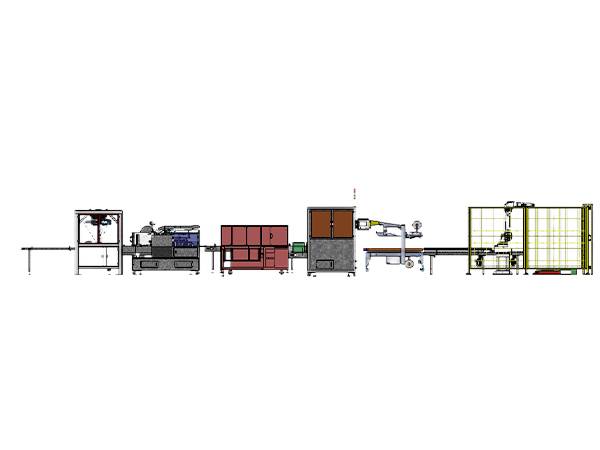

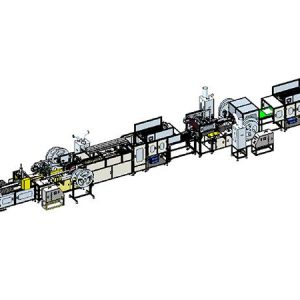

This is a completed packaging machine, including sealing, cutting and film shrinkable wrapping; automatic inverted bottle to the cartoning machine, the machine automatically opens the box, pushing material, folding, glue inserted molding conveyor, automatic labeling, automatic cartoner, automatic organization, automatic opening, loading, sealing palletizing as a whole carton packaging machine, suitable for multiple varieties and multi-specification. It is controlled by PLC microcomputer with automatic alarm and fault indication. It is characterized by HMI control, simple operation and convenient maintenance. High-quality stainless steel and aluminum made, and the surface is polished.

- Power supply: 220 V / 50 Hz

- Power: 6 kW

- Applicable paper tray:

- 126 × 75 × 75 mm

- 108 × 68 × 6 mm

- 135 × 76 × 7 6 mm

- 135 × 68 × 68 mm

- Weight: About 12000 kg

- Carton Requirements: Carton indentation usually at 0.4 mm deep, and the carton needs to have pre-fold effect. If carton opened by hand, it can’t be molded, and the machine can’t open the carton.

- Full automatic control by PLC microcomputer.

- Adopts HMI operating system, which automatically displays the performance data such as cartoning speed, quantity, and cause of failure.

- This machine is equipped with push material anti-collision function.

- This machine has the function of detecting the lack of material in the box frame.

- The machine body adopts high quality stainless steel, paint and aluminum combination

- Multiple specifications can be adjusted within the prescribed range.

- Manual and automatic conversion function.

HMI operation

PLC control

-

Automatic Side Seal Shrink Wrapping Machine

-

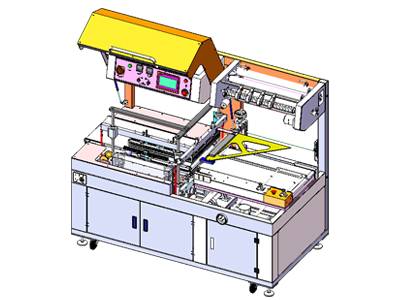

Cartoning Machine

-

Fully Automatic Single Corner Labeling Machine

-

Unpacking, Crating And Sealing

-

Robot Palletizing

| PLM-5545D Automatic L-shape vertical top and bottom sealing and cutting machine |  |

|

|---|---|---|

| Program | Details | |

| Sealing Systems | Heat source | Adoption of stainless steel heating tube, long service life |

| Sealing cutter | Adopt anti-adhesive and high temperature resistant sealing knife, one-time molding, sealing more firmly and beautifully, Teflon coated non-stick film on the outside of the knife. | |

| Sealing cutter temperature control | Adopting Japan “OMRON” digital display temperature controller and imported thermal sensor control, temperature 0-300 °C adjustable. | |

| Sealing size | Electric height control Max. sealing size: L+H <450 mm, W+H < 400 mm,H<170 mm |

|

| Seal protection | Adopt Taiwan Meiji, effectively prevent missealing of packaging objects | |

| Drive system | Taiwan SHAKO cylinder vertical drive control transverse sealing knife, make sure the seal is firm and smooth | |

| Sliding rail | Adopt Japan: “THK” to ensure the sealing knife up and down running smoothly. | |

| Sealing system | Adopt “Taiwan SHAKO” cylinder to ensure the sealing firmly and accurately. | |

| Conveying system | Belt | PU conveying belt |

| Motor | MAILI motors for high speed and smooth conveyance | |

| Test | Adopt American “Banner” photoelectric sensors to accurately and sensitively detect product transportation and stopping. | |

| Recycling system | Motor | MAILI motors,ensure accurate and uniform recycling of waste materials |

| Inductive switch | Adopting Taiwan Meiji to accurately control the time of recycling waste materials | |

| Film feeding system | Motor | MAILI motors,ensure smooth film feeding |

| Inductive switch | Adopt Taiwan Meiji to accurately control the film feeding length | |

| Power supply/power | 3& 380 V, 50/60 Hz, ≤ 4 kW | |

| PLC | Siemens | |

| Contactor | France SCHNEIDER | |

| Intermediate relay | JAPAN IDEC | |

| Touchscreens | Kunlun Tongtai 7 inch, 65000 color screen | |

| Thermostat | Yudian | |

| Emergency switch | JAPAN IDEC | |

| Hole puncher | Multi-position perforator for rapid air venting of the bag during shrinkage | |

| Machine component materials | Carbon steel spraying, the key parts are made of stainless steel plate and aluminum profile to ensure a solid structure. | |

| Packing speed | Varies depending on pack size (1–35 pcs/min) | |

| Air pressure | 6–8 kg/cm2 | |

| Surface treatment requirements | Corrosion-resistant structural material surface spraying or nickel-plated treatment | |

| PLM-5030LW Constant Temperature Shrink Wrapping Machine |  |

|

|---|---|---|

| Program | Details | |

| Heating system | Insulation layer | Made of high-temperature resistant rock wool, low surface temperature when working, reducing heat loss |

| Temperature control | OMRON temperature controller, temperature 0-200 °C | |

| Conveying system | Motor | Taiwan LUSON geared motor |

| Ventilation system | Specially designed air duct system, the product is heated evenly, Japan Minghe wind motor, according to the different products can be adjusted to shrink the partial air volume in the furnace. | |

| Controlling system | Protective switch | Schneider |

| Intermediate relay | Schneider | |

| Thermostat | OMRON | |

| Emergency switch | Schneider | |

| Converter | Schneider | |

| Solid-state Relay | OMRON | |

| Switching power supply | Schneider | |

| Switch | Tend | |

| Machine body | Outer plate | Adopting ordinary carbon steel plate, after bending, surface plastic spraying treatment |

| Inner plate | Adoption of galvanized sheet hydraulics | |

| Shrinkage oven size | (L×W×H) 1500×500×300 mm | |

| Power supply/power | 3 & 380 V / 50 Hz, average 18 kW | |

| Machine size | (L×W×H) 1800×950×1250 mm (Subject to actual machine) | |

Main configuration

| Number | Name | Brand | Place of origin |

| 1 | Main body | Stainless steel & steel / painting | China |

| 2 | Electric components | Schneider/OMRON | France/Japan |

| 3 | PLC | Xinje | China |

| 4 | Touch screen | Xinje | China |

| 5 | Pneumatic component | Airtac | Joint venture |

| 6 | Bearing | Luoyang | China |

| 7 | Converter | Xinje | China |

| 8 | Motor | Starshine drive | China |

| 9 | Hot Melt Adhesive Machine | Nordson | U.S. |

Main configuration

| Name | Brand | QTY. | Name | Brand | QTY |

|---|---|---|---|---|---|

| PLC | Panasonic | 1 set | Header Traction Motor | LEADSHINE/BALE | 1 set |

| Label Sensors | LEUZE/SICK | 1 set | HMI | SAMKOOM/WECON | 1 set |

| Product Sensors | Panasonic | 1 set | |||

| Machine Structural Parts | |||||

| Name | Material | QTY. | Name | Material | QTY |

| Marker head and adjusting mmechanism | Stainless steel, aluminum alloy | 1 set | Traction mechanism | Gold steel, aluminum alloy | 1 set |

| Conveying mechanism | Stainless steel, aluminum alloy | 1 set | Electric box mechanism | Stainless steel, aluminum alloy | 1 set |

| Guide mechanism | Stainless steel, aluminum alloy | 1 set | Corner labeling mechanism | Stainless steel, aluminum alloy, brushes | 1 set |

| Covering mechanism | Stainless steel, aluminum alloy | 1 set | |||

Technical Parameters

- Labeling speed: about 0 – 60 P/min (depending on the product and label size)

- Labeling accuracy: ± 1 mm (excluding product labeling and other errors)

- Applicable product size (L × W × H): 200 × 180 × 100 mm

- Applicable labeling range: length 10 – 100 mm, backing paper width 10 – 100 mm

- Maximum label supply: outer diameter of 300 or less, inner diameter of 76 mm

- Ambient temperature / humidity: 0-50 °C, 15% – 85%

- Voltage specification: AC 220 V, 50 Hz

- Size (L × W × H): 2200 × 1100 × 1500 mm

- Weight: about 170 kg

- Label parameter:

- Label spacing: 2–3 mm ± 0.2 mm (roll material)

- Material: It is recommended that the use of grapheme backing paper, backing paper to avoid cuts or cut marks, affecting the normal operation of the labeling

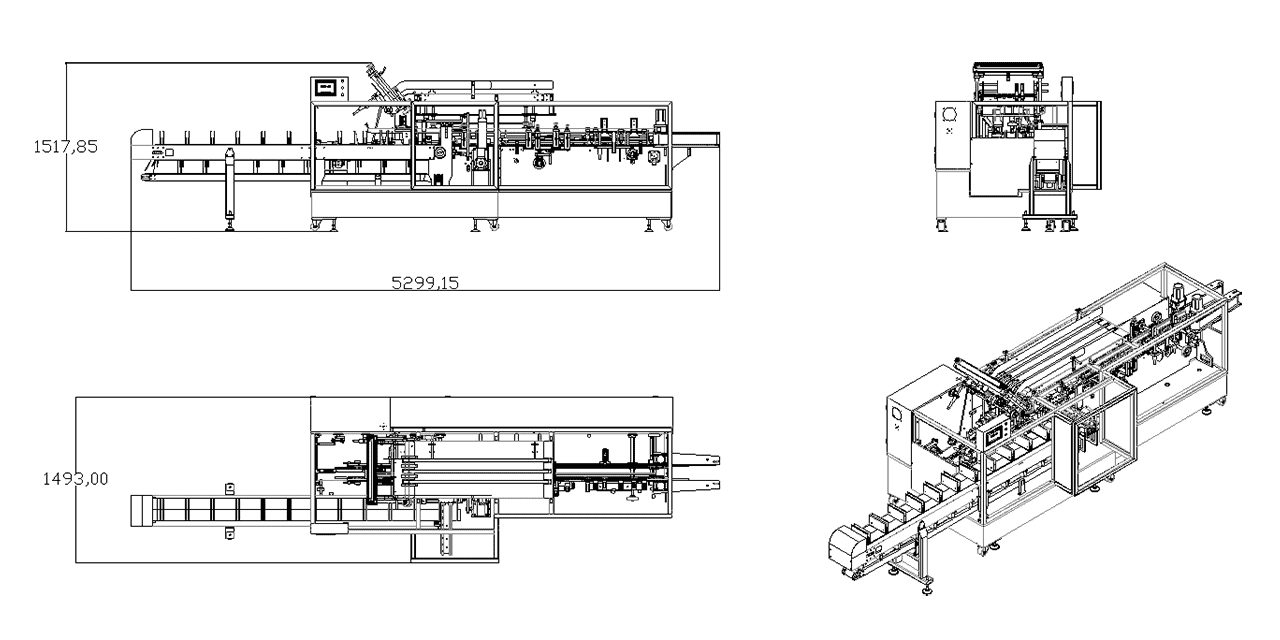

Open Box Molding Machine

- Power supply: 220 V 50 Hz 400 W

- Air pressure: 6 kg/cm2

- Gas consumption: 200 L/min

- Overall dimension (L × W × H): 2000 × 1950 × 1500 mm

- Machine weight: 400 kg

- Carton specification: can be customized according to customers’ carton size.

- Tape width: 4.8 × 7.2 cm

- Molding speed: ≤10 boxes/minute (depending on carton size)

- Production efficiency of single machine: ≥ 95%.

- Carton loss: 1‰

- Carton opening mode: vertical molding

- Power supply: 220 V 50 Hz 400 W

- Electrical configuration:

- PLC control: Germany “Siemens”.

- Contactors: France “Schneider”.

- Sensor: S+D

- Push button switch: France “Schneider”

- Human-machine interface: Xinje

- Cylinder: Taiwan “Yadek”.

- Motor: Taibang

- Power supply: 220 V 50 Hz 400 W

- Working process: suction box → unpacking box → folded front and back paper cover → folded left and right paper cover → seal the bottom

- Environmental conditions:

- Humidity ≤ 98%

- Temperature 0 – 40 ° C.

The whole machine features:

- Equipment design and production in line with the requirements of the production line process and plane layout, beautiful appearance, good manufacturing process

- Low electricity and water consumption, easy and quick operation, adjustment and maintenance

- The machine has good self-safety protection functions, such as overload protection and safety door, etc.

- Alarm function for no tape and no cardboard box.

- Storage mechanism: about 50 unformed cartons can be placed at a time (according to the thickness of the carton), and can be replenished at any time

- Power supply: 220 V 50 Hz 400 W

Crating Models

Connecting the front section of the equipment automatically conveying finishing to the cartoner conveyor belt, the machine is automatically arranged, neatly after the side of the carton pushed loading.

Configuration

| Number | Name | Brand | Place of origin |

| 1 | Main body | Stainless Steel & Steel | China |

| 2 | Electric components | Schneider/OMRON | France/Japan |

| 3 | PLC | Xinje | China |

| 4 | Touch screen | Xinje | China |

| 5 | Pneumatic component | Airtac | Joint venture |

| 6 | Bearing | Luoyang | Siemens |

| 7 | Servo motor | Luoyang | China |

Technical Data

- Power supply: 220 V / 50 Hz

- Power KW: 2.2 kW

- Speed: 1 – 5 case/Min

- Applicable paper tray: (L × W × H)

- 395 × 170 × 141 mm

- 360 × 150 × 123 mm

- 400 × 170 × 150 mm

- 360 × 156 × 150 mm

- Weight: About 1.2 ton

- Carton Requirements:

- carton indentation: 1.0 mm deep

- beveled corners cartons required

Automatic Folding Cover Sealing Machine

- Power supply: 220 V, 50 Hz, 200 W

- Working air pressure: 6 kg/cm2

- External dimensions (L × W × H): 1700 × 930 × 1510 mm

- Table height: 600 mm (adjustable)

- Carton specification: customized according to customers’ carton

- Belt speed: 20 meters/minute

- Tape size: 48 mm or 55 mm

- Sealing tape: kraft tape, BOPP tape

- Electrical configuration

- Contactor: France “Schneider”

- Push button switch: “Siemens” APT

- Pneumatic components: Taiwan “Airtac” / ” SHAKO”

Machine performance

- Manual adjustment of height and width when changing specifications

- Transmission mode adopts the lower two sides of the belt drive.

- Line or stand-alone operation, automatic folding lid, upper and lower one line sealing completed at one time.

- Load: 25 kg

- Arm Length: 1808 mm

- Body Mass: 191 kg

- Protection Level: IP 54 (Axis 4-5-6 IP 67)Protection Level: IP 54 (Axis 4-5-6 IP 67)

- Repeatability Precision: ±0.08 mm

- Application Scenarios: Machine tool loading and unloading, palletizing, handling, assembly, etc.

- Product Features: Six-axis full RV design, good rigidity

Linkage and Motion Range

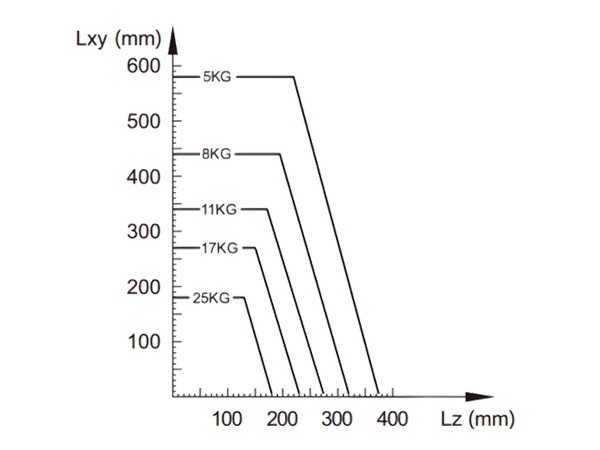

Structural Component Motion Range, Linkage Parameter Diagram

Load Torque Variation Diagram

Interface and Installation Dimension Diagram

Reviews

There are no reviews yet.