Filter adhesive plays an important role in air, oil, water and HVAC filter assembly and manufacturing. Given the vital role of adhesive in the filter production, using the right adhesive makes a big difference in filter assembly and manufacturing.

How to choose the best adhesive for your applications? PLM would like to provide some basic information of our 4 types of filter adhesives to help you to understand and select the right adhesive for your specific application in filter manufacturing process.

-

PU adhesive

- It gives shorter cycle times and can actually be molded to replace the traditional metal end-cap.

- High performance, versatile and applicable to a wide range of substrates

- Good resistance to solvents when cured.

- Stay bonded through a wide range of operating temperatures.

-

Two component filter cartridge adhesive

- Great chemical resistance.

- An excellent record of durability.

- Form tough bonds with high peel strength.

- Better low temperature strength than other adhesives.

- Exceptionally high strength at cryogenic temperatures.

-

One component thermosetting adhesive

- High elasticity, fast curing

- Great resistance to impacts and vibrations

- Impressive mechanical performance

-

Hot melt glue

- Good resistance to high and low temperatures.

- Excellent bond strength and machining characteristics

- Highly chemical and heat resistant

- Good stability, strong adhesion to paper and non-woven fabrics.

Filter adhesives are often used to fabricate numerous filter components, to assemble the filter media itself, to bond the filter media into a frame or end cap or install the gasket and the main functions of each filter adhesive are as follows.

-

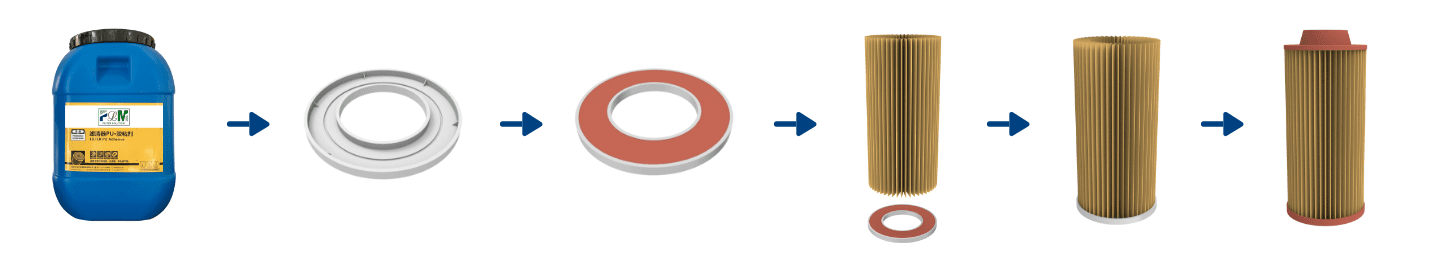

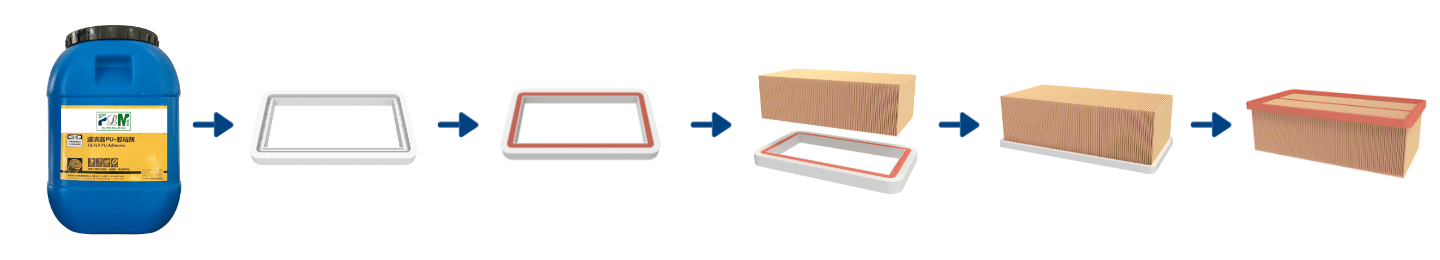

PU AdhesiveFrame Molding. PU adhesives are often used to be molded to form PU air filter frames to replace the traditional metal end caps. It can be used as the air filter frames of both heavy trucks and cars as below.

For heavy truck air filters

For car air filters

-

Range of Application

Commercial vehicle air filter

Engineering machinery air filter

Air compressor air filter

Car air filter

Industrial dust air filter

-

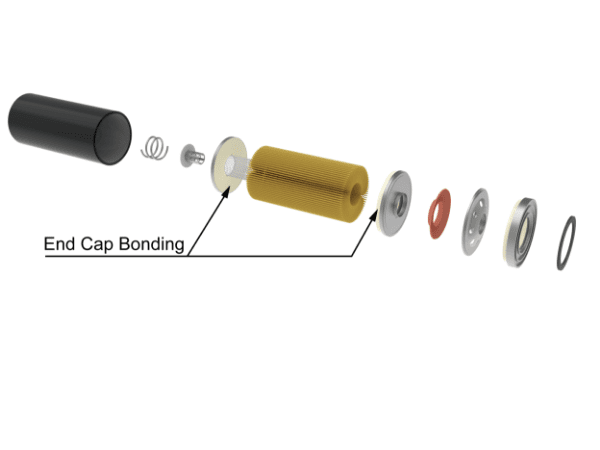

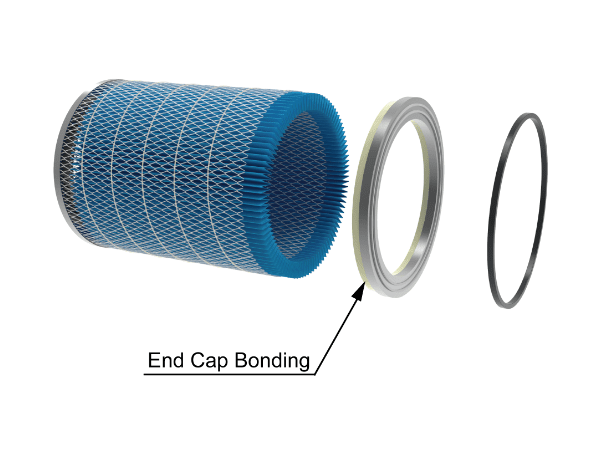

One/Two Component AdhesiveEnd Cap Bonding. Both adhesives are generally used to bond pleated filter media onto the metal end caps.

For car and truck oil filters

For truck air filters

-

Hot Melt Glue

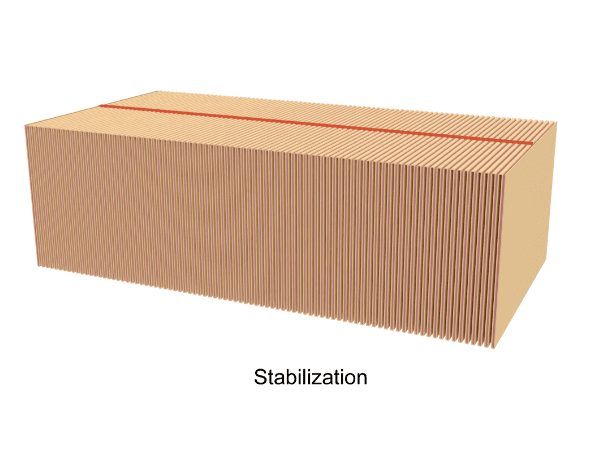

- Stabilization. The glue is often used to keep the pleats separated to ensure uniform flow of the fluid and maximize efficiency and capacity. Spiral beads of adhesives are applied to stabilize the media during use.

- Spiral Warp Bonding. The glue is often applied to filter media or the outer support for spiral wrap bonding to stabilize the media or the filter during use.

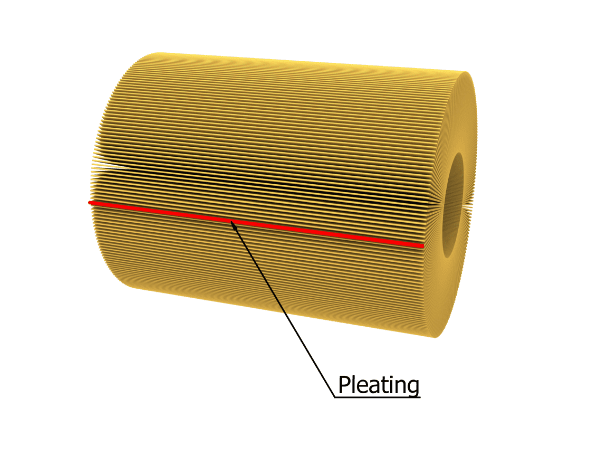

- Pleating. Radial pleating is when the filter media is wrapped into a cylindrical form. The glue is often used to bond the two ends of the cylindrical form together to stabilize the media during use.

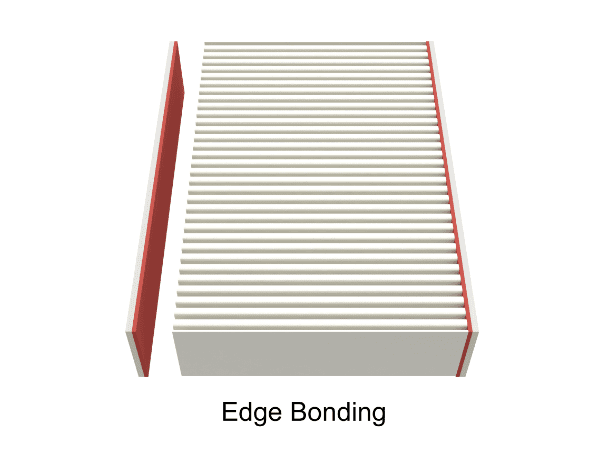

- Edge Bonding. The glue is often used to bond the filter media to the filter edge. It is commonly used in cardboard edge for HVAC filters.

For air filters

For air filters

For air filters

For oil filters

For HVAC filters

| Application | PU Adhesive | Two Component Filter Cartridge Adhesive | One Component Thermosetting Adhesive | Hot Melt Glue |

|---|---|---|---|---|

| Commercial vehicles air filters | √ | √ | √ | √ |

| Passenger cars air filters | √ | √ | √ | √ |

| Construction machinery air filters | √ | √ | √ | √ |

| Cabin air filter | √ | |||

| Air compressor | √ | √ | √ | √ |

| Air cleaner & purifier | √ | √ | √ | √ |

| Vacuum cleaners | √ | √ | √ | √ |

| Hydraulic oil filter | √ | √ | ||

| Fuel filter | √ | √ | √ | |

| Spin-on oil filter elements | √ | √ | √ | |

| Eco fuel & oil filter | √ | √ | ||

| Industrial dust removal | √ | √ | √ |

If you still wonder what kind of filter adhesive is perfect for you, just contact us directly, all your problem will be solved.

Reviews

There are no reviews yet.