Specification

| Test air volume range: | 300–4300 m3/h |

| Test sample specifications (max.): | 1220×1220×300 mm |

| Test resistance range: | 0–1000 Pa |

| Diluter ratio: | 1:100-10000 |

| Test efficiency range: |

|

| Sampling flow: | 28.3 L/min |

| Source of fog and dust: | DEHS |

| Power requirements: | 380 V, 50 Hz, 9 kW |

| Gas source requirements: | 0.6 MPa |

| Covered area: | 5400×4600×2300 mm |

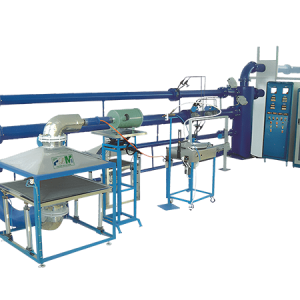

Features

- The high-efficiency filter scanning and inspection platform is controlled by three-axis and other intelligent components to achieve fully automatic inspection. The software operation is simple and convenient. After the test is completed, the system automatically pops up a report. All test data are reflected in the report. The user can choose to print it directly or save it with one click.

- The high-efficiency filter scanning and inspection platform adopts point-by-point scanning function and is equipped with a leak point re-scan function, which can accurately locate leak points and generate leak point maps in the inspection report to facilitate users to repair leak points.

- The isodynamic sampling head and template of the high-efficiency filter scanning and testing platform can be customized according to the different needs of users to meet the testing requirements of different product specifications.

- The high-efficiency filter scanning and testing platform adopts the latest automatic inlet and outlet structure to facilitate users to replace the tested filter.

- The high-efficiency filter scanning and detection platform has an automatic dust adjustment function, allowing users to quickly adjust the concentration required for dust detection.

- The high-efficiency filter scanning and testing platform has its own working clean area to improve the accuracy of equipment testing.

Function

- The high-efficiency filter scanning test bench is a product independently developed and designed by our company. The product design complies with EN1822:2012 (high-efficiency air filter – sub-efficiency, high-efficiency, ultra-high efficiency)

- ASHRAE52.2:2012 (Method for testing general ventilation air cleaning equipment based on efficiency of particle size), GB/T 13554-2008 (High Efficiency Air Filter) and other standards, product main testing

- The average efficiency, lowest point efficiency, leakage point location and resistance at rated air volume of sub-efficiency, high-efficiency and super-efficiency air filters. The products are mainly used by companies in the field of ventilation and air conditioning for product quality control and new product research and development.

Reviews

There are no reviews yet.