Rotary pleating machine is a type of machine designed to automate the folding of paper, non-woven cloth or other materials into pleating shapes. These machines manipulate the paper according to programmed instructions.

Rotary pleating machine is the the major and important machine during air filter, oil filter and other filter production. They can guarantee large quantities of pleating shapes be produced quickly and consistently. They can be programmed to fold various types and sizes of paper, allowing for a wide range of pleating designs to be created.

These machines can significantly speed up the pleating production process and ensure precise and uniform folding.

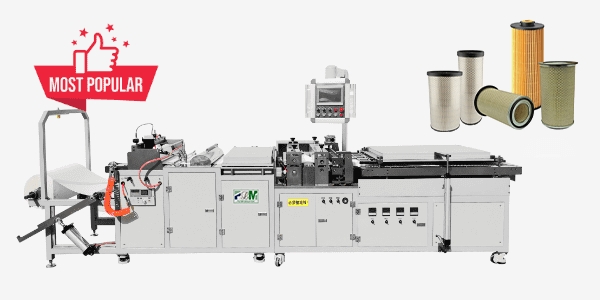

We have many types of Rotary pleating machine during production, and which one has received consistent praise from customers? We recommend that you use PLM-GT-700A Drum Type Air Filter Pleating Machine

This machine is used for pleating and forming the HDAF filter element.

- Auto paper de-coiler

- Paper Pre-slitting machine

- Pre-heating device before pleating

- Auto counter

- Water steam device

- The specification of the drum can be changed arbitrarily

- Roller and gear collecting device

- Pleated paper heat forming and conveyor device

- The pre-slitter uses pneumatic cutting round knife, which is adjusted simply and pressed evenly.

- This machine equips the pre-heating and water steam device, to prevent the paper breaking when roller marking.

- This machine equips the gear collecting system, so to faster the pleating speed and well pleated the paper.

- This high automatic machine has the process of the auto count marking, pleating, pre-heating and forming.

- This machine is computer control and simple operation.

We can design the pleated shape according to your requirements, the following shapes are available for reference:

If you still want to know which pleating machine is the best for you, please contact us directly and all your questions will be solved.

Reviews

There are no reviews yet.