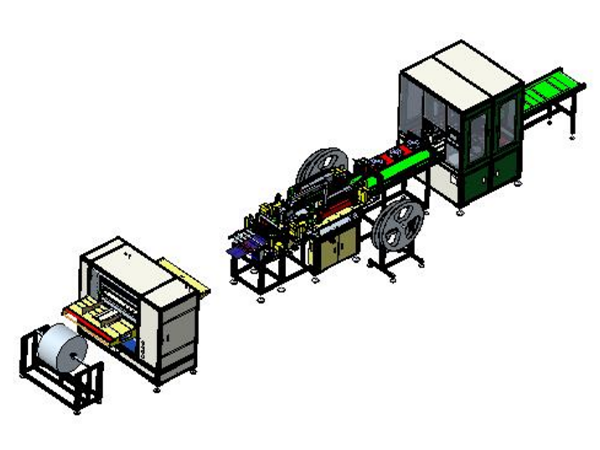

Recently, we developed a new production line of cabin filters, which has less equipment and higher efficiency. Besides, the operation is more convenience than the traditional production lines.

This production line mainly consists of 4 parts: Pleating machine, Automatic stacking machine,automatic side bonding machine and automatic cutting machine.

Action process: Origami forming → automatic stacking → automatic spacing and automatic welting → automatic cutting → automatic blanking

Technical Data

- Applicable Product Size: (L × W × H: MAX.: 600 × 350 × 50 mm,MIN.: 150 × 130 × 15 mm;

- Efficiency: 200 pcs/h (Take 350×350×30 mm as an example)

- Equipment reference size (L × W × H): 10000 × 2200 × 2000 mm

Here, we will show the full line in different views:

Production line front view

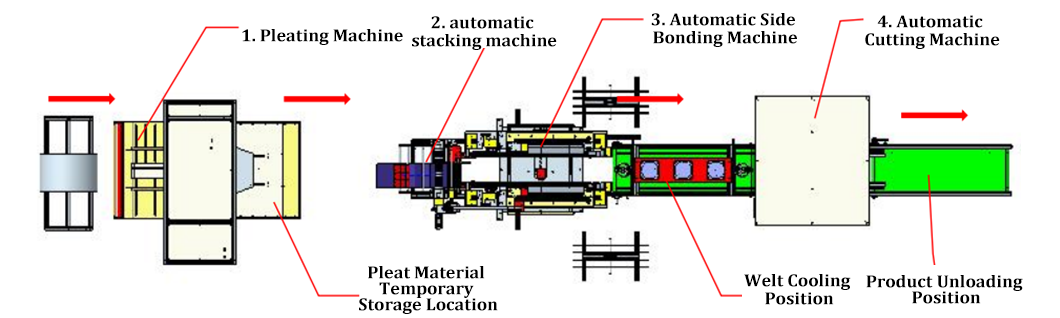

Production line top view

Explain:

- This production line is primarily composed of three major parts: pleating machine, automatic stacking machine, automatic bonding machine, and automatic cutting machine.

- The workflow sequence is: pleating and forming → automatic stacking → automatic spacing and bonding → automatic cutting → automatic unloading.

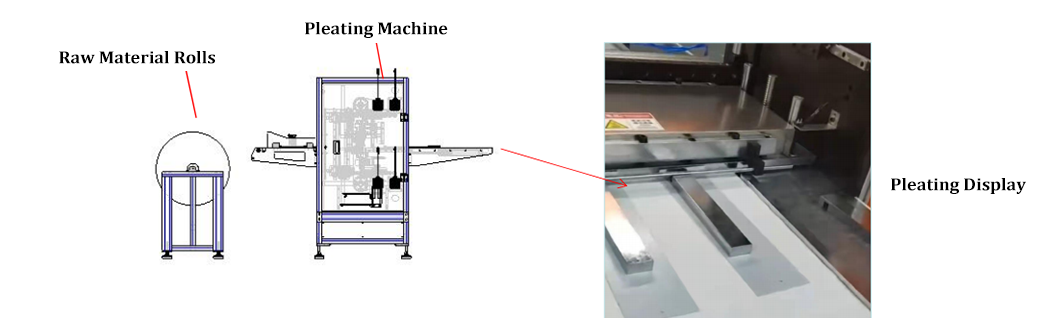

Equipment Introduction – Pleating Machine

Explain:

- This pleating equipment mainly consists of two major parts: the raw material rack and the pleating machine.

- Operational workflow: load the raw material → automatically pleating according to the product height.

- Electrical specifications: Total power of the folding machine: 15 kW, 380 V / 50Hz; Air pressure: 0.6 MPa.

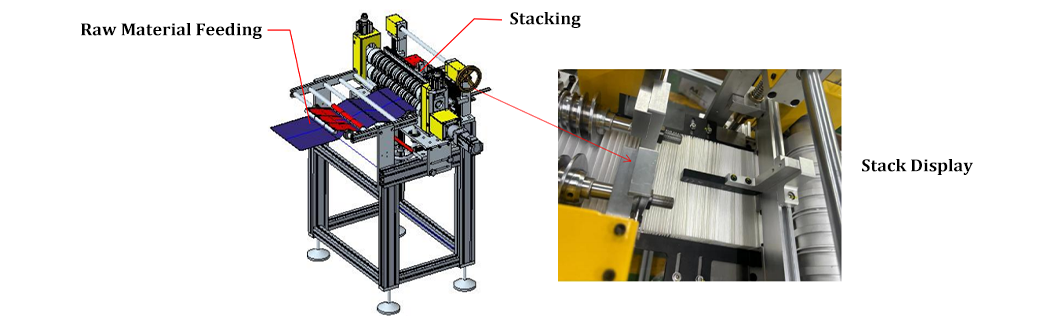

Equipment Introduction – Stacking Machine

Explain:

- This pleating equipment mainly consists of one major part: the automatic stacking machine.

- Operation workflow: Material passes through the tensioning mechanism → Servo motor automatically folds the paper and stacks it.

- Electrical specifications: Total power of the automatic stacker: 4 kW, 220 V / 50 Hz; Air pressure: 0.6 MPa.

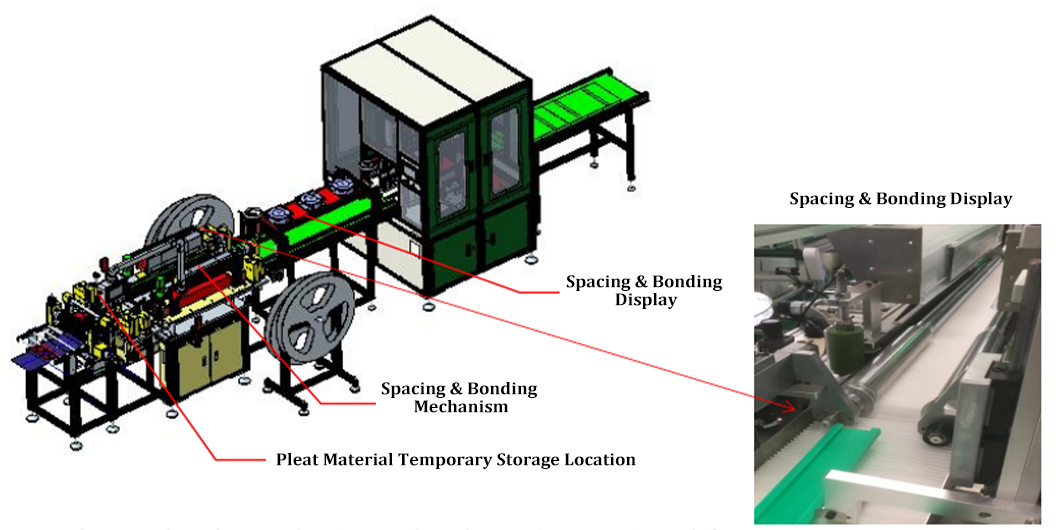

Equipment Introduction – Automatic Side Bonding Machine

Explain:

- This bonding machine primarily consists of three main parts: the loading conveyor, the automatic spacing and bonding mechanism, and the cooling conveyor.

- Operational workflow: Automatic spacing → Automatic bonding.

- Electrical specifications: Total power of the edging machine: 15 kW, 220 V / 50 Hz; Air pressure: 0.6 MPa.

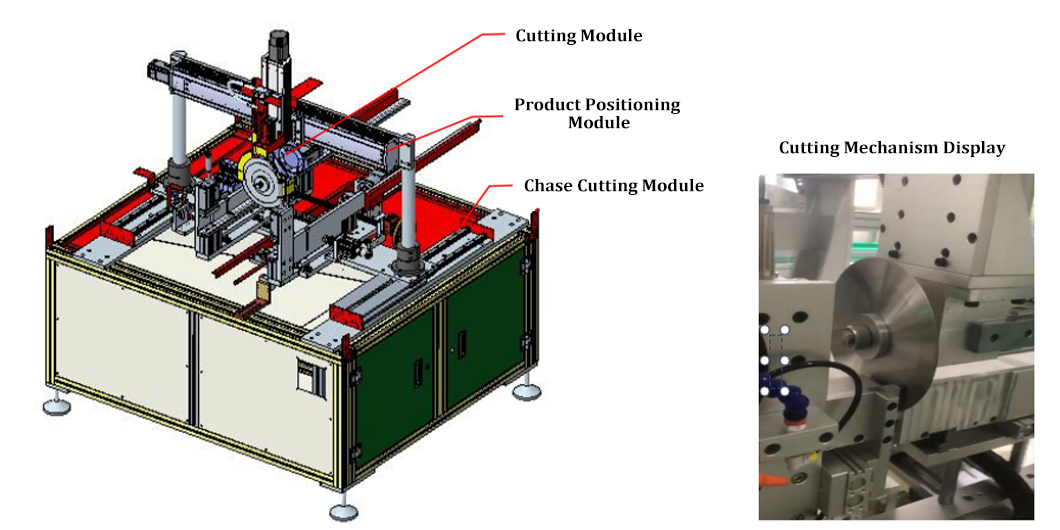

Equipment Introduction – Automatic Cutting Machine

Explain:

- This automatic cutting machine is mainly composed of three major parts: the cutting module, the product positioning module, and the chase cutting module.

- Operational workflow: Automatically cut to the set length based on the preceding data → Automatically perform chase cutting → Automatically discharge the material.

- Electrical specifications: Total power of the three-axis machine: 6KW, 220V/50HZ; Air pressure: 0.6 MPa.

Video